Mechanical Engineering

The Department of Mechanical Engineering is one of the pioneering departments of Rajadhani institute of engineering and technology established in 2009 with a vision of imparting quality education in mechanical engineering and allied domains by inculcating human values for social transformation. The Department of Mechanical Engineering at Rajadhani Institute of Engineering and Technology (RIET) stands as a cornerstone of academic excellence and innovation.

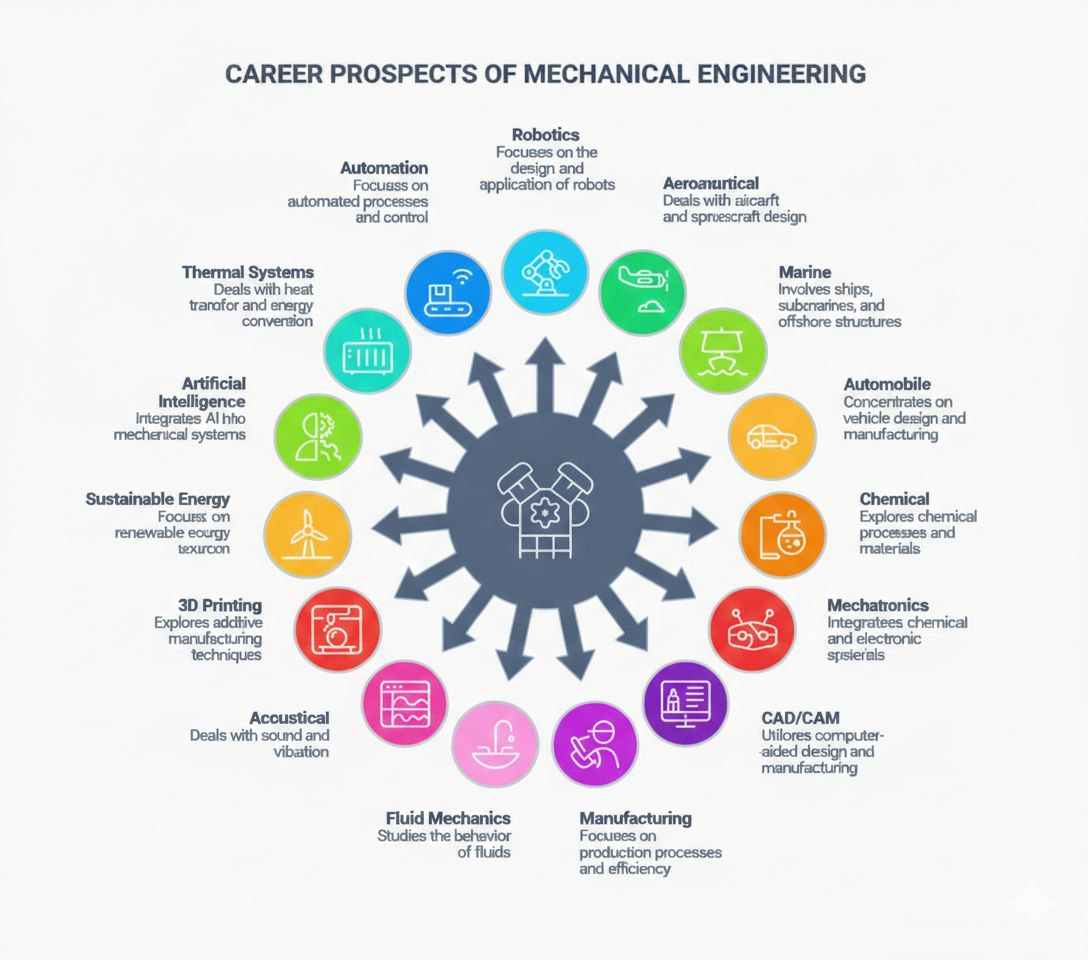

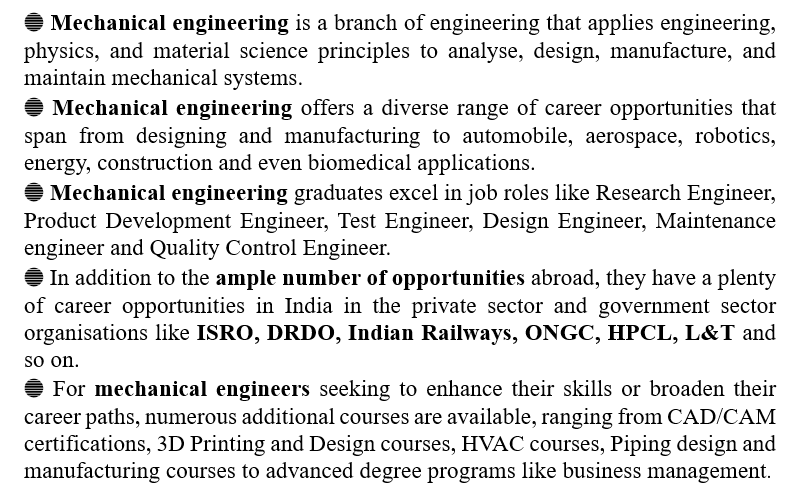

- State-of-the-Art Infrastructure: The department boasts well-equipped laboratories, including advanced facilities for fluid mechanics, thermodynamics, CAD/CAM, material testing, and automation.

- Experienced Faculty: A team of highly qualified and experienced faculty members committed to academic excellence and mentoring students.

- Industry Collaboration: Strategic partnerships with leading industries and organizations for internships, training, and joint research projects.

- Hands-On Learning: Emphasis on experiential learning through workshops, live projects, and industrial visits.

- Research and Innovation: Active involvement in cutting-edge research, with a focus on areas such as renewable energy, robotics, additive manufacturing, and smart materials.

Vision

To be a preferred destination to produce technocrats in Mechanical Engineering fostering academic excellence, research, industry readiness with human values for social transformation.

Mission

M1: To impart quality education through activity based learning and leading -edge technology.

M2: To provide holistic education inculcated with research activities, human and ethical values, societal and industrial commitment, personality development and team spirit

M3: To foster strong industry- institute interaction to develop employable skills and enrich experiential learning through capstone projects.

- Undergraduate Program (B.Tech in Mechanical Engineering): A comprehensive curriculum combining theoretical foundations with practical applications to prepare students for diverse engineering challenges.

- Value-Added Programs: Helps to get certified in emerging fields such as 3D printing, HVAC design, robotics, and IoT integration.

Program Educational Objectives

PEO 1: Graduate shall have strong core and interdisciplinary knowledge, skills and professional accomplishment towards employment in allied industries, higher studies and research.

PEO 2: Graduates shall utilise latest tools and rapidly changing technologies to analyse, design and develop sustainable systems, testing and manufacturing for real life applications.

PEO 3: Graduates shall practice multidisciplinary approach, ethics, good communication, team spirit to evolve as competent technocrats and entrepreneurs.

Programme Outcomes

- Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- Problem analysis: Identify, formulate, review research literature, and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety and the environmental considerations.

- Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data and synthesis of the information to provide valid conclusions.

- Modern tool usage: Create, select and apply appropriate techniques, resources and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts and demonstrate the knowledge of and need for sustainable development.

- Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- Individual and team work: Function effectively as an individual and as a member or leader in diverse teams and in multidisciplinary settings.

- Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations and give and receive clear instructions.

- Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- Life-long learning: Recognize the need for and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Programme Specific Outcomes

- Mechanical Design – Capable to Design Mechanical Systems with updated software tools and equipment’s/Processes to meet desired Specifications and requirements within realistic constraints to solve real time mechanical/societal problems.

- Managing Efficiency – Develop Capabilities to address the challenges in the Energy Sector and Develop Energy Efficient Systems.

- Industrial Application – Manage the Resources in an Organization more effectively and efficiently in the Dynamic Industrial Environment.

Department & Classrooms

The teachers’ room is the place where staff can relax before or after class, consult with colleagues, plan lessons, discuss educational issues and socialize. Creating a space where they can relax in comfort away from their job role will help support their work/life balance. Smart Classrooms are equipped with technological resources, such as interactive projectors & multimedia devices. These Classrooms aim to keep students engaged in learning. It involves the use of visual and audio means rather than only textbooks.

MANUFACTURING LAB I & II

Manufacturing technology lab enhances students to study and practice the various machining operations that can be performed in lathe, shaping, drilling, milling etc. and equip students with the practical knowledge required in the manufacturing /production.

Facilities

- Lathe machine

- Shaping machine

- Slotting machine

- Plaining machine

- CNC machine

- Fully automated milling machine

- Semi-automated milling machine

- Horizontal band saw machine

- Radial drilling machine

- Surface grinding machine

- Cylindrical grinding machine

- Tool & cutter grinding machine

THERMAL ENGINEERING LAB

The primary purpose of the-laboratory thermal engineering is-to show students the experimental methods-on thermal energies on various engines-and demonstrate their operational procedures. These values can be further used to determine other fuel properties. Thermal engineering plays a serious role in industries such as automotive, aerospace, power generation, and manufacturing. It is fundamental to the design and operation of internal combustion engines, refrigeration units, and thermal power plants.

Facilities

- Benson boiler

- Steam generator

- Parallel flow – Counter flow heat exchanger

- Air conditioning test rig

- Refrigeration test rig

- Heat pipe demonstrator

- Forced convection apparatus

- Stefen-boltzman apparatus

- Pin – fin apparatus

- Thermal conductivity of liquid

- Thermal conductivity of composite wall

- Thermal conductivity of metal bar

- Emissivity measurement apparatus

- Rectangular fin array apparatus

- Multifluid heat pipe test apparatus

- Natural convection apparatus

FLUID MECHANICS AND MACHINES LAB

Fluid Mechanics & Hydraulic Machines Laboratory is a well-equipped laboratory which provides ideas on hydraulic turbine and carry out their performance study useful hydel power plants. Examine and understand pump working characteristics under given constraints. The Fluid mechanics lab helps the students to understand the characteristics of water in a pipe flow or open channel. The application of water pumps, and use of notches are explained through the laboratory setup.

Facilities

- Reynolds theorem apparatus

- Orifice apparatus

- Bernoulli’s theorem apparatus

- Venturimeter

- Orificemeter

- Pipe friction apparatus

- Notch apparatus

- Pelton wheel turbine

- Francis turbine

- Kaplan turbine

- Metacentric height apparatus

- Reciprocating pump test rig

- Centrifugal pump test rig

- Hydraulic ram test rig

INTERNAL COMBUSTION ENGINES LAB

An IC engine lab, or internal combustion engine lab, is a facility that conducts research on internal combustion engines (ICEs). The goal of IC engine labs is to improve the performance of ICEs, reduce emissions, and develop new technologies. Methods for testing internal combustion engines include measuring important performance parameters like friction power, indicated power, brake power, and efficiency. Engineers test engines to compare performance and identify areas for improvement.

Facilities

- Four stroke single cylinder diesel engine

- Four stroke single cylinder petrol engine

- Basic Two stroke single cylinder petrol engine

- Heavy Two stroke single cylinder petrol engine

- Four stroke twin cylinder diesel engine

- Four stroke four cylinder petrol engine

METROLOGY & INSTRUMENTATION LAB

Metrology is the science of measurement and how it’s applied. By contrast to instrumentation, metrology is not just about the physical and routine making of measurements, it is more about the infrastructure in place that ensures we are confident in the accuracy of the measurement. The calibration of various transducers and instruments performances are studied and also analyzed the static and dynamic characteristics of the various instruments.

Facilities

- Autocollimator

- Profile projector

- Tool makers microscope

- Metallurgical microscope

- Polishing machine

- Sine bar

- Slip gauge and precision measuring instruments

BASIC MECHANICAL WORKSHOP

The Basic Mechanical Workshop at the Mechanical Engineering Department is designed to provide students with hands-on experience in various fabrication/manufacturing processes. The aim of a workshop is to bring a group of people together around a specific subject. The aim is to encourage learning, collaboration, problem-solving or the creation of new ideas. Unlike a traditional meeting or conference, a workshop is often interactive and participative.

Facilities

- Foundry

- Black smithy

- Basic machines

- Power cutter

- Plumbing

- welding

- Carpentry

- Fitting

- Sheet metal cutting

MECHANICAL LAB

One of the most diverse and versatile engineering fields, mechanical engineering is the study of objects and systems in motion. As such, the field of mechanical engineering touches virtually every aspect of modern life, including the human body, a highly complex machine.

Facilities

- Whirling of shaft apparatus

- Universal governor

- Motorized gyroscope apparatus

- Bomb calorimeter

2019 SCHEME SYLLABUS: SEMESTER 1

2019 SCHEME SYLLABUS: SEMESTER 2

2019 SCHEME SYLLABUS: SEMESTER 3

2019 SCHEME SYLLABUS: SEMESTER 4

2019 SCHEME SYLLABUS: SEMESTER 5&6

2019 SCHEME SYLLABUS: SEMESTER 7&8

2024 SCHEME SYLLABUS: SEMESTER 1&2

2024 SCHEME SYLLABUS: SEMESTER 1 & 2 (AUTONOMOUS)

2025 SCHEME SYLLABUS: SEMESTER 1 & 2 (AUTONOMOUS)

WORKSHOPS AND FDPs

- Manoj A , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ High Performance Computing” from 20/1/2025 to 25/1/2025.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Vijil J , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Vijil J , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “Vehicle Electrification: Future Mobility Trends” from 27/01/2025 to 01/02/2025.

- Amal J Anil , Assistant Professor of Mechanical engineering department has attended FDP on “Future Trends in Building Information Modelling (BIM)” on 25th January 2025.

- Manoj A , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ High Performance Computing” from 20/1/2025 to 25/1/2025.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Vijil J , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “Vehicle Electrification: Future Mobility Trends” from 27/01/2025 to 01/02/2025.

- Amal J Anil , Assistant Professor of Mechanical engineering department has attended FDP on “Future Trends in Building Information Modelling (BIM)” on 25th January 2025.

- Joe Jeba Rajan K, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Education 5.0:Innovate,Educate,Elevate” organised by Rajadhani Business School from 10th July 2024 – 12th July 2024.

- Manoj A, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Sree Raj M P, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Amal J Anil, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Bindu S S, Associate Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Sreemahesh M P, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Krishnakumar K, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024..

- Sourav R Vimal, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Amal J Anil, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Vijil J, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Niju V S, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Sourav R Vimal, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Ullas S, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Joe Jeba Rajan K, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Sreeraj M P, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Vijil J,, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Vijil J,, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Drone technology” organised by AICTE training and learning academy from 08/01/2024 to 13/01/2024.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended a workshop on “NBA accreditation” organised by NITTTR, Kalamassery from 13/05/2024 to 17/05/2024.

- Vijil J,, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “3D printing and product development” organised by AICTE training and learning academy from 29/11/2023 to 05/12/2023.

- Manoj A , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Ullas S , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Krishnalal M S , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Vijil J , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Sourav R Vimal , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Niju V S , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Sreemahesh M P , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Sreeraj M P , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

List of Publications

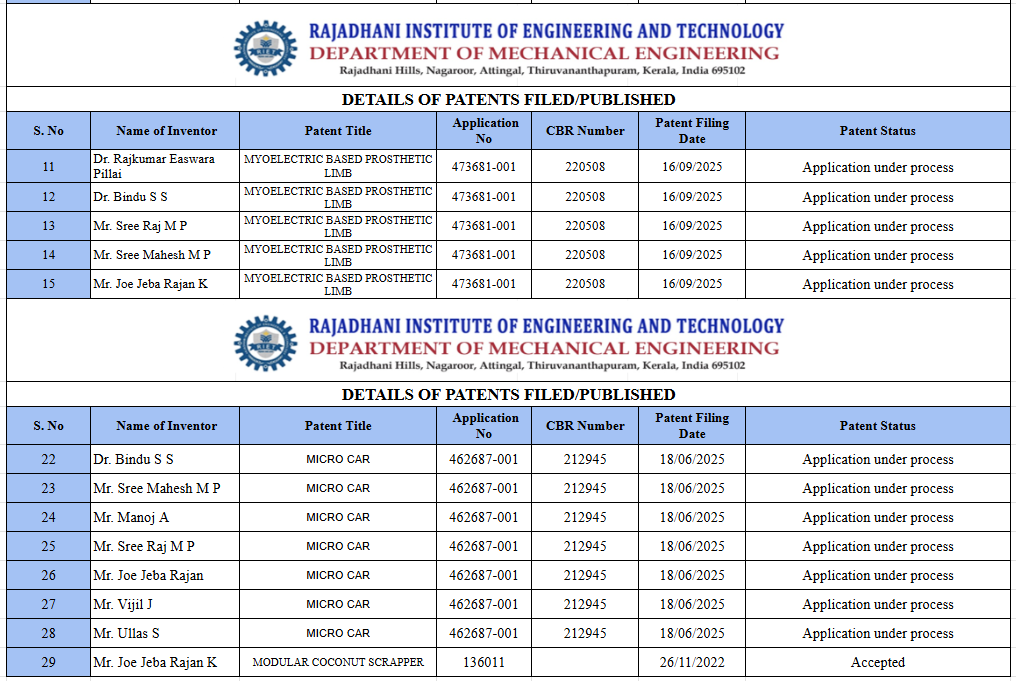

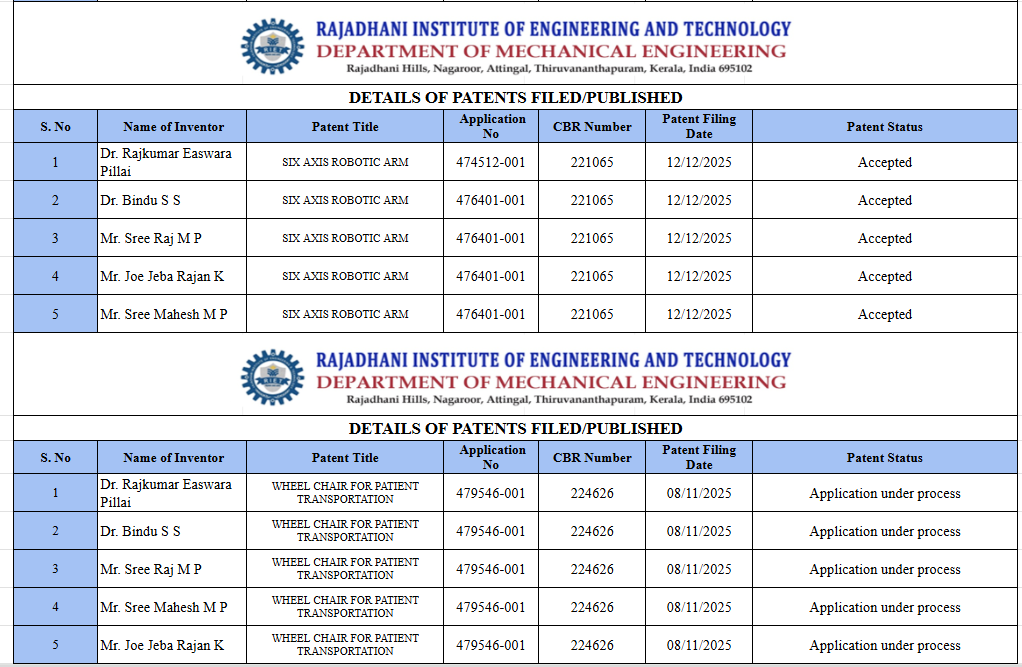

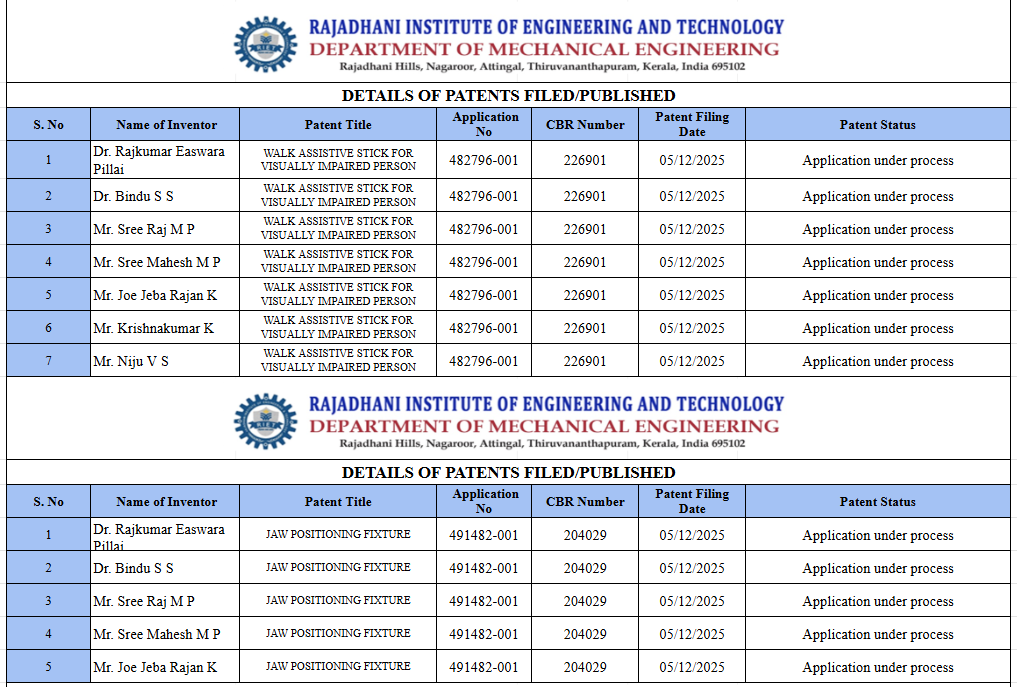

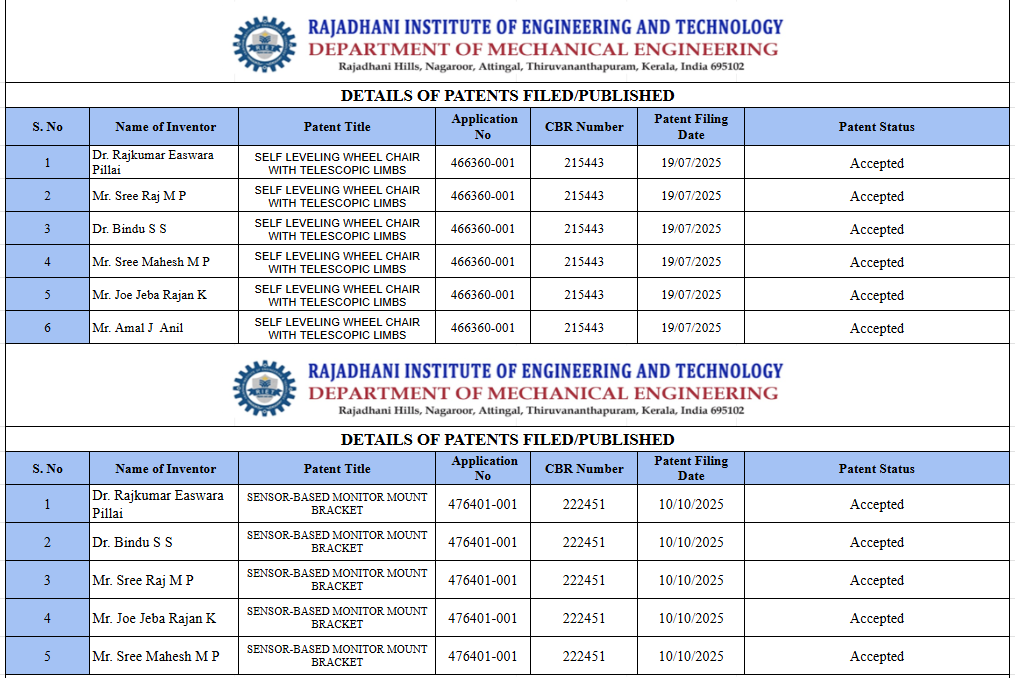

List of Patents Filed/Published

List of Book Chapters Published

Faculty Development Programme Attended

Conference Presentations

Participation in national and international technical competitions like SAE Baja and robotics challenges.

Regular workshops, seminars, and guest lectures by industry experts and alumni.

Active student chapters of professional bodies like SAE, and ISTE.

…

Expert talk on Final Year project potentialities and opportunities by Mrs. Bindhu S S

Expert talk by Dr.J.Bruce Ralphin Rose On Computational Fluid Dynamics

‘HERTZ’ THE LOUDEST SUPER BIKE ‘MEXIBITZA’ WAS CONDUCTED AS PART OF THE COLLEGE CULTURAL FEST ITIHA 2018

TRAINING ON FEAST BY VSSC FOR OUR FACULTY AND STUDENTS – CAREER ORIENTATION PROGRAM

CAREER ORIENTATION SESSION BY MR. BALRAM SHANKAR

A MOTIVATION SESSION FOR OUR STUDENTS – A MOTIVATION SESSION FOR OUR STUDENTS BY MRS PUSHPA BHAI

Best Paper award on title Natural Ventilation performance of wind tower. Mr. Hareesh Krishnan H, Asst. Prof. in ME received.

Best Paper award on title Natural Ventilation performance of wind tower with modified head exchanger device at Kerala Technological Congress 2017 and 9th Rank in Thermal Engineering, CUSAT.

1st Rank in Thermal Engineering, CUSAT. Mr.Jenish P Varghese , Asst. Prof. in ME got 1st Rank in Thermal Engineering, CUSAT

Newsletters 2023 Volume 1

Newsletters 2023 Volume 2

Newsletters 2024 Volume 1

Newsletters 2024 Volume 2

Newsletters 2025 Volume 1

- Manoj A , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ High Performance Computing” from 20/1/2025 to 25/1/2025.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Vijil J , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Vijil J , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “Vehicle Electrification: Future Mobility Trends” from 27/01/2025 to 01/02/2025.

- Amal J Anil , Assistant Professor of Mechanical engineering department has attended FDP on “Future Trends in Building Information Modelling (BIM)” on 25th January 2025.

- Manoj A , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Sree Raj M P , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ High Performance Computing” from 20/1/2025 to 25/1/2025.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Vijil J , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “ Smart farming; role of Technology in millet production” from 13/01/2025 to 18/01/2025.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended AICTE ATAL sponsored Faculty Development Programme on “Vehicle Electrification: Future Mobility Trends” from 27/01/2025 to 01/02/2025.

- Amal J Anil , Assistant Professor of Mechanical engineering department has attended FDP on “Future Trends in Building Information Modelling (BIM)” on 25th January 2025.

- Joe Jeba Rajan K, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Education 5.0:Innovate,Educate,Elevate” organised by Rajadhani Business School from 10th July 2024 – 12th July 2024.

- Manoj A, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Sree Raj M P, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Amal J Anil, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Bindu S S, Associate Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Sreemahesh M P, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Krishnakumar K, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024..

- Sourav R Vimal, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Amal J Anil, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Vijil J, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Niju V S, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Fusion fundamentals CAD and CAM” by AUTODESK from 11/12/2024 to 13/12/2024.

- Sourav R Vimal, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Ullas S, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Joe Jeba Rajan K, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Sreeraj M P, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Vijil J,, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “AI driven semi conductor technology” organised by AICTE training and learning academy from 15/01/2024 to 20/01/2024.

- Vijil J,, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “Drone technology” organised by AICTE training and learning academy from 08/01/2024 to 13/01/2024.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended a workshop on “NBA accreditation” organised by NITTTR, Kalamassery from 13/05/2024 to 17/05/2024.

- Vijil J,, Assistant Professor of Mechanical engineering department has attended a Faculty Development Programme on “3D printing and product development” organised by AICTE training and learning academy from 29/11/2023 to 05/12/2023.

- Manoj A , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Krishnakumar K , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Ullas S , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Krishnalal M S , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Vijil J , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Sourav R Vimal , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Niju V S , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Joe Jeba Rajan K , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Sreemahesh M P , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

- Sreeraj M P , Assistant Professor of Mechanical engineering department has attended ISTE sponsored Faculty Development Programme on “3D Printing & Additive Manufacturing” from 18/04/2022 to 22/04/2022.

Innovations by the Faculty in Teaching and Learning

Instructional Methods and Innovative pedagogical initiatives:

The Department of Mechanical Engineering utilizes the Learning Management System – Linways AMS to oversee all academic activities. The course structure incorporates innovate initiatives are embedded within the curriculum to enhance the quality of learning. The use of innovative methods in teaching and learning has the potential not only to improve education but achieve student. Development. Innovative practices are introduced in teaching and learning to stimulate students curiosity across various domains, encourage them to question assumptions, a All these innovative methods adopted in teaching and learning, in the long term, help students build team spirit, uphold moral principles, take on social responsibilities, share information, and Both qualitative and quantitative data demonstrate the effectiveness of innovative techniques. The qualitative component enhances social conduct and comprehension. It also helps alter encouraged and the quantitative component enhances academic success. The Department of Mechanical Engineering faculty members have implemented various innovative and best practices

Use of Instructional Methods and Pedagogical Initiatives

Step 1: The course allocation is done about a month before the commencement of semester. The faculty members are asked for their choice of course by the time table coordinator. PAC assigned the courses to the faculty members based on their choice and expertise.

Step 2: The faculty members are asked to prepare a detailed course plan for the courses.

Step 3: Course handouts and Course materials are prepared following the lesson plan and course outcomes.

Step 4: Faculty members use various pedagogical methods for effective Teaching-Learning process. The pedagogical methods used by the faculty members are enlisted in the following table:

Instructional Methods and Delivery Details

Instructional Methods by faculty

Various innovative instructional materials

YouTube channel of faculty members and their link

Mr Joe Jeba Rajan

Management for Engineers

https://youtu.be/6cJBwQOFc9M?si=hDNnnN7bGqr1wg4C

Mr Joe Jeba Rajan

Programming in C

https://youtu.be/LXsTKLqJpAw?si=CFA3nxFpPmhub3sP

Mr Manoj A

Engineering Graphics

https://www.youtube.com/watch?v=zKX1juGsYBI

Mr Manoj A

Dynamics of Machinery

https://www.youtube.com/watch?v=tjsEKAHzUL0

Mr Sreeraj M P

Industrial Engineering

https://youtu.be/ECfiQNnwNoY?si=vFlFvCP4FrMG1SQ7

Mr Sreeraj M P

Sustainable Engineering

https://youtu.be/d1JcmGAWq68?si=T5pETtZSBm6U1j7M

Online Lecture and Assessment

In an online lecture, the educator communicates course content (using a whiteboard, PowerPoint presentation, or similar tools) to students in a virtual setting instead of an auditorium. Online assessment is the process of evaluating students’ learning progress and accomplishments using digital tools and technologies. Numerous formats are possible, including tests, assignments, surveys, and quizzes.

Prepared 3D & Cut-Sectional Model

The development of imagination is a crucial step in the learning process. 3D models and their demonstrations make it easier to understand and visualize objects, which help enhance thinking capacity and capability when drawing views of objects. In a class review, students suggested that interaction with such a method led to a better understanding of engineering drawing, particularly in orthographic projections and isometric views.

The objective of these activities is to expand technical understanding by actively engaging students in real world and personally meaningful projects. Project-Based Learning (PBL) starts with a problem and requires students to analyse and apply learned information and theories to solve it. Students work in groups to manage and complete assigned tasks. Teachers and industry experts provide guidance to execute projects. The Department of Mechanical Engineering conducts these activities regularly. Students further explore their work for their projects and are encouraged to participate.

Hands-On Diagrams (Sketch) – Tutorial-Based Class

This method involves hands-on practice sessions in which students draw sketches related to various engineering subjects, such as Engineering Graphics and Kinematics of Mechanisms. In these sessions, drawing neat sketches of velocity, acceleration, and cam profiles is essential for understanding the working principles of specific mechanisms and concepts. Faculty members from the Department of Mechanical Engineering regularly explain how to create schematic diagrams and illustrate their functionality.

On-the-Job Teaching

This innovative teaching method involves using actual tools, equipment, and materials to provide a better understanding and real-world experience. It aids in imparting lifelong learning to students. Faculty members use this approach to demonstrate assembly and operation, particularly in subjects such as

Engineering Metrology and IC Engines.

Furthermore, students perform minor adjustments or routine maintenance on their own. To complete project designs and create models, they also utilize manufacturing and welding resources in practical applications.

Hands-on training Workshops `

The Department of Mechanical Engineering organizes workshops on DESIGN TO REALITY CAD + CAM to bridge the gap between industry and academia. The objective of such seminars and workshops is to provide hands-on exposure to students. These workshops emphasize these fields and help bridge the curriculum gap.

Content beyond Syllabus

The faculty members in the Department of Mechanical Engineering believe that going above and beyond the prescribed curriculum helps students learn more, increases their enthusiasm for the topic, and improves their knowledge of advanced modern tool usage for project work, analysis, and data interpretation These practices

result in enhanced teaching and learning as well as improved attendance.

Industry /Academia Expert Lectures /Alumni Lecture (Innovative tool for updating knowledge)

The goal is to examine current technology, industry expectations, and progress through lectures and discussions with representatives from academia, industry, and alumni. The ability to connect theoretical knowledge with practical

applications of technological advancements benefits students by expanding their understanding and incorporating valuable insights from real-world experience. Students receive information on the latest technological advancements, industry demands, and opportunities for higher education, among other relevant topics.

NPTEL (National Programme on Technology Enhanced Learning)

Technology-Enhanced Learning is a learning platform for higher education. The National Programme on

Technology Enhanced Learning (NPTEL) is one of the major initiatives in this domain. By completing these courses, faculty members of the department acquire new knowledge and enhance their skills, which in turn improve their teaching effectiveness. Additionally, teachers encourage students to enroll in such programs to gain new knowledge and improve their learning abilities in their respective disciplines.

Peer learning

Peer learning is an educational practice in which students interact with their peers to achieve academic goals. Outstanding students mentor slow learners to enhance their understanding of the subject. Courses. are identified based on students’ performance assessments, and difficult topics are discussed during extra class hours to reinforce learning.

Google Classroom

The use of Google Classroom integrates students into the digital learning revolution. It provides access to a question bank, study guides, and assignments at their convenience. The student(s) who are all absent, can independently access classroom resources from home, ensuring that they do not fall behind in their studies.

Smart Class Room (Digital System)

A smart classroom is a digital learning environment that enhances the teaching process by displaying instructional content on a screen rather than a blackboard.

This method improves lecture quality and creates an engaging classroom atmosphere. Smart classrooms

aim to keep students actively involved in learning by incorporating virtual and audio-based teaching tools in addition to traditional textbooks.

Assessment and Evaluation

Conventional Methods:

· Continuous Internal Assessment (CIA) tests

· Class tests

· Tutorials

· Assignments